North American Biochar 2024 was held in Sacramento last week and it was standing room only during the plenary sessions in the expansive SAFE Conference Center near the state capitol. There was a TechCon conference going on in the Hyatt across the street but, somewhat surprisingly for California, it was tiny and half-hearted by comparison.

If you were to go back a quarter century those tables would be flipped. Just launch a dot com and your Series A was assured. Raise the champagne flutes. Massaratis all around. Ask any of the young unicorns or VCs then about biochar and you’d have drawn a blank stare. Biochar existed only in the rarified atmosphere of academic labs or on the trowels of archaeologists excavating river banks in Brazil.

Today ninety-nine percent of those flashy tech startups are gone. Biochar is quietly ascendant. As I have discovered from recent public talks, knowledge of biochar is remarkably limited here on the Left Coast, compared to audiences I have spoken to in Finland, Italy, Australia and China. This could be a cautionary lesson but there is a difference between the boom and bust of tech and biochar. Biochar is inevitable. The industry has crossed a point where it has become unstoppable. Any number of companies in this field that exist today are at one ten thousandth of the size they will be at maturity, in as little as 10 years from now. Many will stay at that size for centuries, should humanity survive.

Flipping the Industrial Paradigm

There is a paradigm shift underway. Kathleen Draper’s and my book, Burn: Using Fire to Cool the Earth, showed only a fraction of the change underway. We worried in 2018 we were overstating the case, but now we know we were understating. What we got right was that the economics of the next two hundred years will be a mirror image of the past two hundred years.

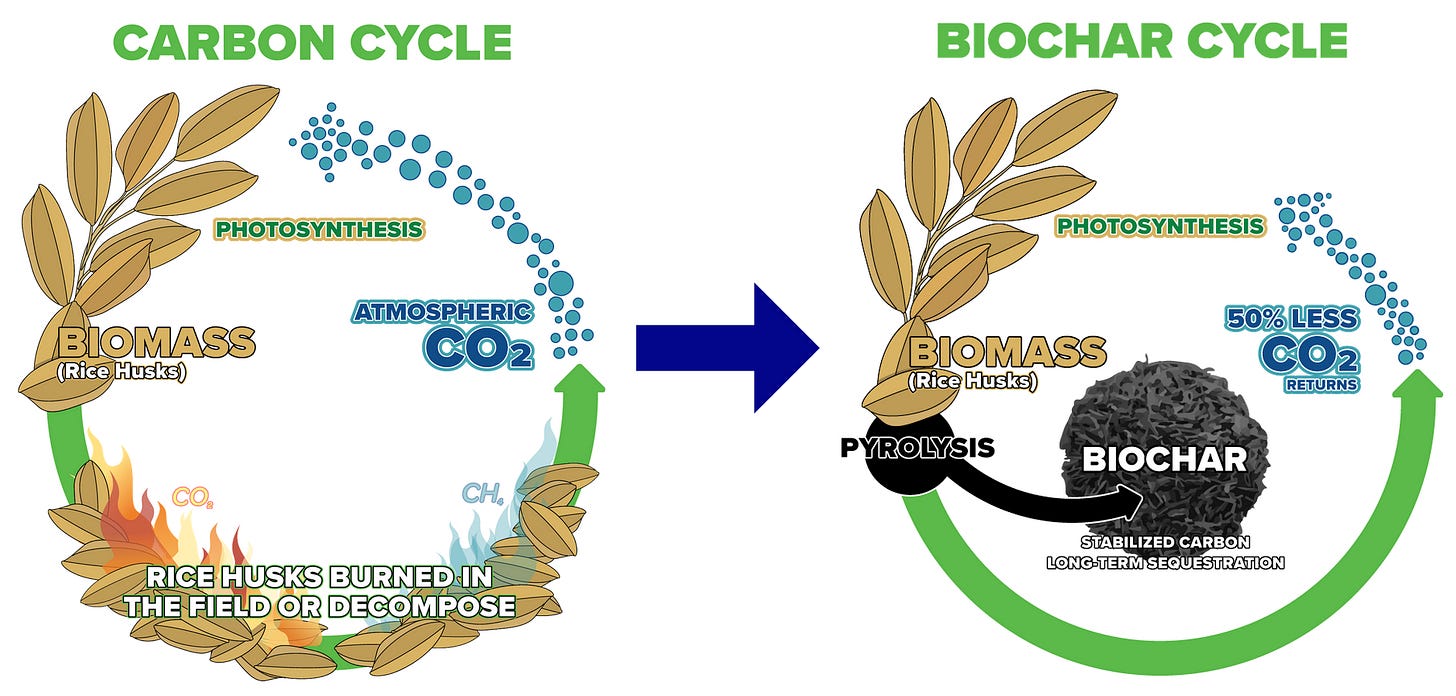

It is not a case of de-industrialization (although that cannot be excluded given the number of new black swans landing on the pond daily), but a reversal of how progress has been made. Instead of taking carbon from the earth, burning it for energy, and disposing of the effluent to the atmosphere and ocean, we will be taking carbon from the sky and sea, producing net energy with fire, and sequestering that carbon for millennia in the earth.

We will build our 21st-century civilization from the carbon we withdraw from the wastes and pollutants of the 20th century. That means everything from bioenergy and abundant fields of food to skyscrapers, highways, bridges and ports. It means clothing woven from bamboo biochar; home cooking and heating that draw more carbon out of the atmosphere than they emit; gardens that do not over-nitrify waterways or bankrupt farmers from the high cost of fossil fertilizer addiction, but supply nutrient-dense, healthy organic produce; and biodiverse ecosystem regeneration.

One of the shibboleths employed by critics is easily put to rest. They say biochar can’t possibly scale enough to matter in reversing climate change because the entire biomass of the planet—all the animals, plants, forests, algae, and people—contains 550 gigatons (a gigaton is one billion tons) of carbon (550 GtC). Plants are about 450 Gt of that, or 82%, and their photosynthesis draws carbon out of the atmosphere. Intercepting carbon’s return by not allowing the biomass to decay to greenhouse gases and instead converting it to mineralized carbon with a durability measured in the thousands to millions of years (biochar) has the effect of restoring the atmosphere's chemistry and cooling the planet.

Doubling time for biochar production capacity globally jumped from 9 months in 2021 to 3.6 months in 2023.

Legacy carbon pollution from the industrial age constitutes about 800 billion tons of carbon in atmosphere and ocean (they are a coupled system) so even if the ENTIRE 450 billion tons of carbon in plants were converted to biochar, the critics argue, it would not be enough to reverse climate change.

Of course, that is not a good argument about why we shouldn’t use biochar because none of the climate solutions we know about is a whole solution, and each can contribute its small part. Each is one Waldorf on the salad bar, as Stacey Randecker hastens to add. But the argument fails on a more fundamental point—our linear pattern of processing information in three dimensions instead of four. The fourth dimension is time.

Plants don’t just grow one and done. They encore every season. Earth’s 450 billion tons of plant biomass renews on a timescale that varies by species but generally from years to decades, or in the case of algae, hours to days.

Chasing China

Let us take the example of just one of the more than 200 biochar producing factories China has built in the past 5 years. It draws biomass crop wastes from a surrounding agricultural region. Indeed, these 200 plants have been sited specifically to serve in a hub and spoke fashion to reduce transportation of biomass into the factory and fertilizer out to the farms. The government has constructed entire, well-designed ecovillages to provide a robust workforce for this integrated system. Our model plant takes in 130,000 tons/year (about ten truckloads per day) of crop waste. It outputs 32500 tons of biochar and 10000 gallons of bio-oils annually. This represents an annual CO2 drawdown of roughly 100,000 tons from the atmosphere and ocean (thorough life cycle analysis would sharpen the calculation). Unlike other types of removal (DACCS, BECCS, mineralization, etc.), there is no extra operating cost for that scrubbing service; it is just a side benefit of fertilizer production. Those 200 new plants combined remove something on the order of 20 million tons (20 MtCO2*) every year.

*Carbon dioxide withdrawal can be calculated by multiplying metric tonnes by 0.8 (average inert carbon content of biochar) and 3.667 (coefficient for conversion to CO2).

Perhaps the more important point is that they are already doing this, and this is just one early example in a world of nearly 200 countries all planning to do this. By comparison, to date 27 Direct Air Capture plants have been commissioned worldwide, capturing 0.01MtCO2/y at a cost of hundreds of millions of dollars and euros. DAC deployment, subsidized by tax money, is projected to sequester 75 MtCO2/y by 2050. [IEA, 2024] Meanwhile, biochar carbon removal was 1.34 MtCO2/y in 2023 at a profit to producers of about $35 million dollars. According to an industry survey still in progress, production will be 7.87 MtCO2/y in 2025. It will likely pass DAC’s 2050 goal in 2035.

While feedstocks are a limiting factor when only using crop residues or only making biochar for fertilizer, those limits vanish when we discover the superior qualities of biochar in construction, road building, carbon fiber, polymers, epoxies, batteries, and other uses. Suddenly the world of contaminated municipal waste, sewage biosolids, unrecyclable plastic, and myriad carbon waste streams beckons.

We may have already passed the point where concrete outweighs the combined carbon mass of every tree, bush and shrub on the planet

A second shibboleth is “why bother gathering carbon from algae in the ocean and making it into biochar (potentially a feedstock source far larger than crop waste) when we could just sink the algae to the sea bed and sequester it that way?” This notion has been debunked by marine biologists who point to the biological carbon pump that extends even to the deepest darkest depths to bring carbon back to the surface where it will return to the atmosphere.

Each year normal ocean circulation withdraws 1,300 GtC from the atmosphere and returns about 80-90 percent, although warming may be slowing the pump. On the downward trip, 85% is zooplankton fecal pellets and 15% is sinking phytoplankton aggregates. On the return trip to the surface, carbon molecules ride whale poop and gas bubbles. These pathways have different sequestration times, with an average of 50-140 years to complete the full cycle. In terms of sequestration permanence, that is millennia briefer than biochar.

Another ridiculous claim from critics of biochar is that because it is black it will absorb sunlight and speed global warming. Anyone who has used biochar will tell you it does little good to spread it around the surface of a garden. It needs to be at the plant roots to work its magic. We do this on a large scale with keyline or chisel plows and injection systems or at small scale with a hoe.

Repaving Paradise

Sacramento seemed an especially apt location for a biochar conference exploring the potential of the industry to scale. Nearly 20 years ago, when Governor Arnold “The Terminator” Schwarzenegger was approaching the end of his first term, he got the California Global Warming Solutions Act through the statehouse. Well ahead of the rest of the world, that law required the State Air Resources Board to ensure that statewide greenhouse gas emissions would be reduced to at least 40% below the 1990 level by 2030. It required the SARB to prepare and approve, and update at least once every 5 years, a scoping plan for achieving the maximum technologically feasible and cost-effective reductions in greenhouse gases by 2020.

Updating the Act in 2021, California’s General Assembly required the SARB, by July 1, 2023, to develop a comprehensive strategy for the state's cement sector to achieve net-zero emissions of greenhouse gases associated with cement used within the state as soon as possible, but no later than December 31, 2045. The Act required the state board, in developing this comprehensive strategy, to define a metric for greenhouse gas intensity and to measure reductions, coordinate and consult with other state agencies, prioritize actions that leverage state and federal incentives, take measures to support market demand and propose financial incentives to encourage the switch.

Sweden, by comparison, has required all aspects of hardscape infrastructure to achieve climate neutrality by 2045, with interim targets of a 15% reduction in GHG emissions by 2020, compared to 2015 values, and a 30 percent reduction by 2025.

The construction industry in California is now legally required to reduce the climate pollution of cement used within the state to 40% below the 2019 average levels by December 31, 2035. By July 1, 2028, SARB must evaluate the feasibility of interim targets and adjust the targets upwards or downwards, as provided, to deliver on the required goals.

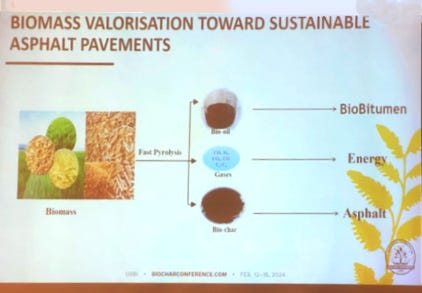

The European Bitumen Association released the life-cycle inventory for bitumen in 2020, showing that producing one ton of asphalt requires energy consumption of 2830.69 MJ and releases 189.12 KtCO2e (Reeves, 2020).

Between 4 and 8 percent of global CO2 emissions come from concrete. Most of that is from the production stage of cement, where giant kilns fueled by oil, coal or fossil gas take tons of crushed limestone to a temperature of 1500°C to separate calcium oxide (lime) from calcium carbonate (stone). 900 kg of CO2 is emitted in the fabrication of every ton of cement. Seven percent of that is from mining and transportation. The remainder is the process of dry kilning the cement.

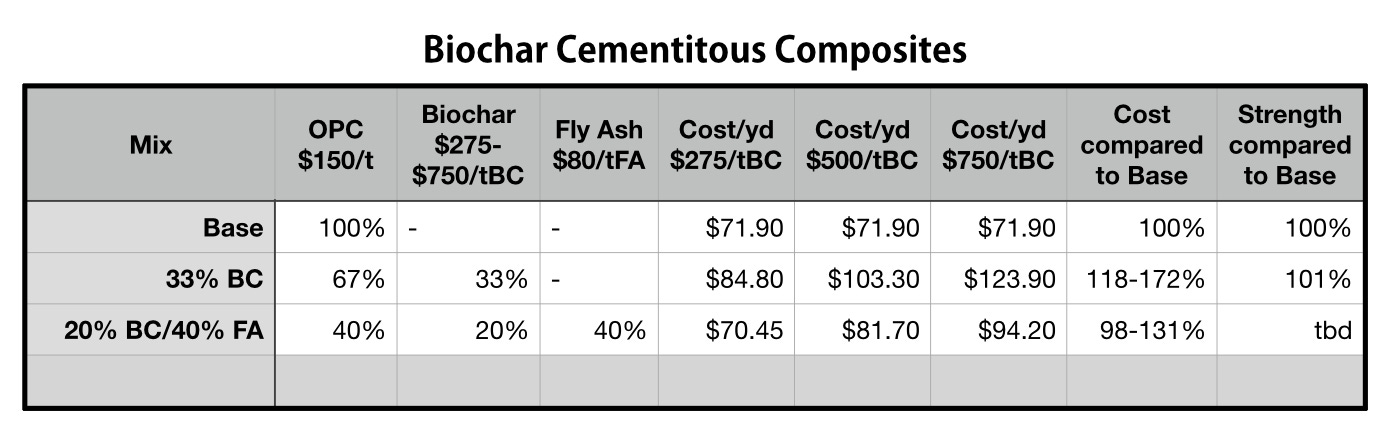

One way to reduce the CO2 intensity would be to include more fly ash content (up to 80% is possible for some common applications like patios and concrete blocks). Fly ash is what goes up with smoke or falls to the bottom of the firebox when you are burning coal. Content varies depending on the coal, but most fly ash is high in silicon dioxide, calcium oxide and aluminum oxide, all valuable structural minerals for concrete, plaster, and epoxies.

Fly ash is one of the largest waste streams in the US. Some of it is produced from waste-to-energy plants, but because that can contain more toxic elements than coal it is categorized as hazardous waste. Historically most fly ash went into the atmosphere and ocean. Today more than half is landfilled but 43% is finding its way back to commercial use. That is one way the State may be able to reach its 2035 target—more fly ash. But note: if you are not burning coal or toxic waste, you are not making much fly ash.

Another choice could be biochar. When Kathleen and I wrote Burn we calculated that the non-agricultural markets for biochar would greatly exceed those of farming and gardening. The drawdown potential in hardscape is 11 times greater—55 billion tons of CO2 annually versus 5 billion tons. Carbon Action Tracker estimates 2023 greenhouse gas (GHG) emissions from cement at 53 billion tons expressed as carbon dioxide equivalents (GtCO2e). That’s almost the same as biochar’s potential but the hitch is feedstock. When you calculate all the crop residues and forestry wastes and factor in processing losses, you are back to a 5 to 10 GtCO2e/y potential.

Cementing Biochar

When we contemplate converting photosynthetic material to biochar, if the end use is going to soils we have to be careful that it is clean—no toxic residues, heavy metals, pharmaceuticals, or microplastics. Those concerns are largely absent if the biochar will be entombed in high-rise buildings, highways, or port facilities being relocated uphill from rising seas. Even in road surfaces, which can degrade from use, the potential toxicity is vanishingly small compared to the inordinate toxic emissions secretly coming off of bitumen in fossil asphalt today and unrecycled plastic content can reduce it further. For biochar producers, feedstock supplies can greatly expand. They can include sewage, municipal wastes, plastics, contaminated seaweeds, and more.

Biochar can be used as a replacement for fine aggregates

Bio-oils can be used as a replacement for bitumen

High silica biochar (rice husk, bamboo) can be used as a replacement for cement

The higher the silica content, the higher the pozzolanic reactivity

Biochar can improve the hardness and rutting resistance of concrete and asphalt

Biochar improves the thermal insulating properties of concrete and coolth of asphalt

Biochar improves the sound absorption properties of concrete and leaching or wear of asphalt

Concrete is the most widely used substance on Earth after water

It is growing at 2.5% annually

It is responsible for between 5 and 9% of CO2 emissions (Aviation is 2%)

1 ton of cement production = 0.9 tons of CO2 released

Around 4.25 billion tons of cement are produced annually

US producers can also register for avoidance credits of 0.517 tCOe per ton of biochar used and drawdown carbon credits based on content.

Normal repairs and resurfacing smear asphalt over a million miles (2.2 million km) annually. Globally, another 330,000 miles of new road are added. If you begin to also prepare subsurface roadways with biochar aggregates (which are stronger and more durable, prevent frost heaves and potholes, filter rainwater, cool the surface in summer, etc.) the market grows to the scaling limits for biochar feedstocks.

At 300 tons per mile of road surface and 30,000 tons in grading surface, the potential road use alone for biochar is 10 billion tons/y or 28 GtCO2e/y (at 75% 1000-year carbon content). If we can simultaneously reduce emissions across all sectors to carbon-neutral, then we begin withdrawing carbon from legacy emissions. To get back to pre-industrial concentrations we will need to withdraw approximately 3 trillion tons CO2.

The ocean will try to equilibrate by off-gassing. If we could drop concentration by 1 gigaton per year, getting to normal will take us 3000 years. If we can net remove 10 Gt/y it would take only 300 years. Withdrawing 50 Gt/y would restore the climate of the Holocene in 60 years. A combination of biochar hardscape with reforestation, marine permaculture and putting back the whales in the oceans could, in combination, accomplish 50 Gt/y with no feedstock bottleneck.

And now it seems likely California will show us the way.

Thanks, Arnold.

References

Bennett, Bert, Large Scale Biomass Gasification and the Co-Production of Biochar and Bioenergy, North American Biochar Conference, 2024

Kessler, Amy M, and Chuck Hassebrook, Navigating the Future: Biochar Policy and Permitting Perspectives, North American Biochar Conference, 2024

Eagle, Bryan, Rice Hull and Rice Straw biochar applications, North American Biochar Conference, 2024

Gray, Myles, Biochar Industry Survey Results, North American Biochar Conference, 2024

Lerchenmüller, Hansjörg, Scaling Biochar Carbon Removal to Climate Relevance, North American Biochar Conference, 2024

Let, Alexander, Biochar and bio-oil as bitumen replacement, North American Biochar Conference, 2024

McLaughlin, Hugh, Methods for measuring biochar properties and how they determine value and performance, North American Biochar Conference, 2024

Mulqueen, Daniel, Biochar and Plant Derived Carbons in High Value Applications, Properties and Potential, North American Biochar Conference, 2024

Nassiri, Somayeh, Biochar concrete: challenges and opportunities, North American Biochar Conference, 2024

Nowicki, Michael, Tim DeVries, and David A. Siegel. "Quantifying the carbon export and sequestration pathways of the ocean's biological carbon pump." Global Biogeochemical Cycles 36, no. 3 (2022): e2021GB007083.

Reeves, S., A. Hewitt, and A. Pepler. “PPR960 Review and update of the asPECT carbon footprinting tool for asphalt road pavements in Euroasphalt and Eurobitumen, PPR960 The Future of Transportation, Eurasphalt & Eurobitumen Congress, 2020

Sanei, Hamed, et al. "Assessing biochar's permanence: An inertinite benchmark." International Journal of Coal Geology 281 (2024): 104409.

Seman-Varner, Rachel, Scaling up Biochar Use in Agriculture for Soil Health and Climate Mitigation, North American Biochar Conference, 2024

Tunstall, Lori, The feasibility of biochar as a cement replacement to reduce concrete's carbon footprint, North American Biochar Conference, 2024

Zhu, Siyue, Xiantao Qin, Ziri Xu, and Mingliang Xing. "Life cycle assessment of energy consumption and carbon emissions of a green maintenance material for asphalt pavement: Warm mix OUFC-5." Journal of Cleaner Production 428 (2023): 139481.

There is a growing recognition that a viable path forward is towards a new carbon economy, one that goes beyond zero emissions and runs the industrial carbon cycle backwards — taking CO2 from the atmosphere and ocean and burying it in the ground. The triple bottom line of this new economy is antifragility, regeneration, and resilience.

Meanwhile, let’s end these wars. We support peace in the West Bank and Gaza and the efforts by the Center for Constitutional Rights, National Lawyers Guild, Government of South Africa and others to bring an immediate cessation to the war. Global Village Institute has sponsored the Green Kibbutz network in Israel and the Marda Permaculture Farm in the West Bank for over 30 years and will continue to do so, with your assistance. We aid Ukrainian families seeking refuge in ecovillages and permaculture farms along the Green Road and work to heal collective trauma through the Pocket Project. You can donate by directing donations to us at ecovillage@thefarm.org. You can read all about it on the Global Village Institute website (GVIx.org). Thank you for your support.

Help me get my blog posted every week. All Patreon donations and Blogger, Substack and Medium subscriptions are needed and welcomed. For reasons unrevealed to us, Meta, Facebook and Instagram have blocked our accounts. You are how we make this happen. Your contributions can be made to Global Village Institute, a tax-deductible 501(c)(3) charity. PowerUp! donors on Patreon get an autographed book off each first press run. Please help if you can.

#RestorationGeneration

“There are the good tipping points, the tipping points in public consciousness when it comes to addressing this crisis, and I think we are very close to that.”

— Climate Scientist Michael Mann, January 13, 2021.